Safety padlocks have been designed to include features that will in part be shared with their security padlock cousins but equally, there will be some that are in total contrast to a common security padlock. The most important aspect of a Lockout Tagout system with regards to padlocks is the lock number control (we call this our Sentinel programme) where it is vital that these are controlled to ensure no unknown duplication takes place which could result in the accidental removal of somebody’s padlock and re-energisation of the equipment resulting in possible fatal consequences.

All padlocks should therefore have the lock number clearly marked on BOTH the body and key to avoid any confusion. Ideally, the padlocks should then be marked (engraved or etched) to associate them to either a person or the plant to be locked out.

The only standard applicable to Safety Padlocks relates to the United States centred Occupational Health and Safety Administration (OSHA) where the requirement under OSHA 1910.147 is that they are “substantial enough to prevent removal without excessive force” and colour is used to differentiate from parts of the plant. The UK regulations through HSE do not stipulate padlock requirements but the Management of Health and Safety at Work Regulations 1999 reinforces the control of safety systems.

The shackle diameters of safety padlocks generally matches the lockout device requirements to securely lockout the equipment using padlocks, hasps and devices. There are some instances on smaller devices where a smaller diameter shackle is needed and these are available as a more specialist product.

Padlocks are manufactured in different materials that, in some cases, are not suitable for security padlocks but are chosen for other safety-specific benefits. The shackles do not need to be hardened and this then helps if the shackle needs to be cut to aid removal in the event of a rogue lock not being removed.

Brass padlocks with brass shackles have been the cornerstone of the Lockout process for many years. The construction means they are relatively compact and the brass shackle gives non-spark benefits. They can be engraved well to assign to person or plant.

Nylon bodied padlocks are becoming a popular option having been drawn across through the US OSHA regulations where the colour coding is a key feature. They are bigger than the brass locks but share a similar weight and are seen to be different from Security padlocks such that they serve no attraction for personal security uses away from the workplace. Some people do not like them as they do not feel as robust as the brass padlocks.

Aluminium bodied padlocks are growing in popularity due to them offering the variety of bright colours through their anodized bodies and take the form of a padlock that feels far more robust than their nylon bodied counterpart. The clean surfaces take etching well for easy customisation that is very visible to others.

The padlocks are keyed in different systems and these are as follows:

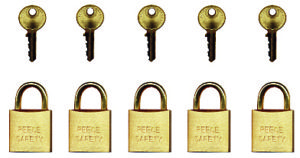

Keyed to Differ; popularly known as “Differs”, is the standard safety padlock keying method.

Keyed Alike padlocks are used for shared locks used in job handover and used in keyed alike sets.

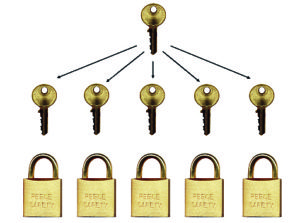

Master and Differ padlocks are often thought to give the ultimate solution to lockout where one key can open all locks if accidentally left locked on the equipment.

Keyed Different Padlocks

Using keyed different (KD) padlocks means that each employee affected can be issued with a controlled numbered padlock knowing that no other keys on site will open the padlock. The number of differs will be sufficiently high to avoid any duplication across all sites for an organisation and the supplier should offer to make sure these numbers are strictly controlled in supplying orders. This KD method satisfies the mantra of “one employee, one lock!”. A common mistake seen is the assumption that security padlocks will serve the same purpose – often a store will only have 20-30 differs on the shelf as normally only one lock is used at a time!

Often 2 keys are supplied where the second is held in a secure key cabinet for emergency removal. Alternatively, some are requested with a single key which guarantees absolutely that no other keys are on site to open the lock.

- Only ONE key will open this lock – subject to lock number recording and control

- Simple lock number management to individuals

- Easy to replace padlocks if damaged or lost

- Normally the lower priced solution

- Having the lock number marked on the body and key makes control of lock numbers possible

Keyed Alike Padlocks

The use of keyed alike (KA) padlocks initially seems in conflict with the control reinforced in lock number control but there are situations where their use works well.

Keyed Alike sets

A large piece of plant will often involve multiple Isolation Points and a single engineer may often work on such equipment. Conventionally they will need individual keys to open each padlock and this naturally needs extra time and frustration. A keyed alike set of 4-5 padlocks with a single key makes this job so much easier. The lock number of each set is again controlled as per KD padlocks and marked on key and lock body.

They are also often used in major plant lockout as common locks and located on lockout station with group lock box – padlocks used by engineer when multiple locks are necessary and uses personal lock to lock single key in lock box.

Shared handover padlocks

If an engineer visits the equipment and cannot complete the maintenance operation the equipment must remain isolated and locked out to avoid any accidental re-energisation. In such cases shared KA padlocks will be used and left on the equipment, with an ID tag advising of status, to be removed and re-cycled by the following engineer. The KA locks will be used in addition to the KD personal lock on any style of hasp so that the individual’s safety is protected – the KA lock is then left in place and picked up by the follow-on worker.

- Strict control of lock numbers for KA sets and normally supplied with only one or two keys

- Make sure KA sets are marked up with lock numbers and engraved with worker name

- Shared padlocks do not need lock number control

- Handover locks for field engineers seems to work and losses of locks is not high

Master and Differ Padlocks

Master and Differ (MD) padlocks are less popular in lockout systems despite the initial obvious appeal of a single key opening all locks in the event of a lock being left in place in error, without damage to the padlock. The individual padlocks have a separate Differ number that operate as a KD padlock and subject to the same padlock number control and unique lock number identification. Hidden away securely is the Master key that can be used, in a strictly controlled process to prevent accidental removal, to remove a rogue padlock. The downsides to this system are quite significant in that the use of the master key system reduces the physical difference between the pins for the differs which may lead to the opening of another padlock through time with wear.

Another consideration is that the padlocks will be supplied as a MD suite which will often have an extended lead time in the original supply. Any replacements must then match this master suite so you tied into this system until the whole system is lost or removed. It has been known that the control of the Master key fails and all the locks need removal for fear of the Master key reappearing – people always borrow such things “for a minute!”

- Simple padlock removal in event of erroneous lock left in place – just make sure Master key security is at the highest level as it may result in whole system being removed if lost

- Replacements will have long lead time and must match original Master suite

- Generally the most expensive solution for Lockout padlocks

- Make sure all individual Differs are marked with the numbers on lock and key and then accurately recorded as per KD padlocks to avoid duplication across sites

UK

UK US

US